The PAIA approach to energy and carbon footprinting asks the following questions:

- Can we target data collection efforts by quantifying carbon impact through highly underspecified and low-resolution data?

- Can a set of high-level product attributes be enough information to understand the drivers of global warming potential impact?

- Is it possible for firms to share confidential data through the creation of industry average benchmarks?

MSL has employed two strategies to meet these goals: data screening and refinement and the Product Attribute to Impact Algorithm (PAIA).

Data Screening and Refinement

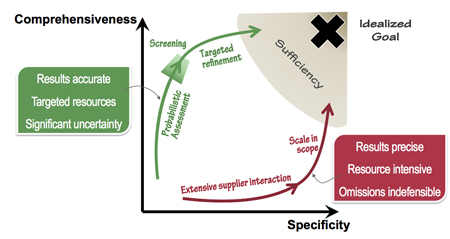

There is a tension between the complexity of a product and its associated supply chains and the need to calculate a result quickly and efficiently. As shown in Figure 2, there are two approaches to LCA that get to the idealized goal of a defensible, sufficient carbon footprint. To reach this goal, one must strike a balance between comprehensiveness and specificity in data collection, often under tight budget and time constraints. Often, LCA practitioners focus data collection efforts on manufacturing processes or product components that they perceive to be the most important. However, the omission of data creates an issue of with the confidence in the results, where the omission of a potentially critical impact cannot be defended.

Possible approaches to reaching a robust and defensible LCA result.

Through this approach, a product is analyzed from a low-resolution lens first, through a comprehensive but imprecise and low-fidelity screening of the entire life cycle that takes into account the uncertainty of the information. Existing data can be used to create this estimate, such as a Bill of Activities or Life Cycle Inventory (LCI) data. The uncertainty data is assembled through the analysis of LCI databases, manufacturing data, government or third party usage studies, or by looking at potential extreme variations within a product’s manufacturing process (e.g. one supplier may ship by train while one may ship by truck). Carbon and energy hot spots in materials and manufacturing can be determined from this process, allowing limited resources to be directed to data collection within the areas that require the most attention.

Product Attribute to Impact Algorithm (PAIA)

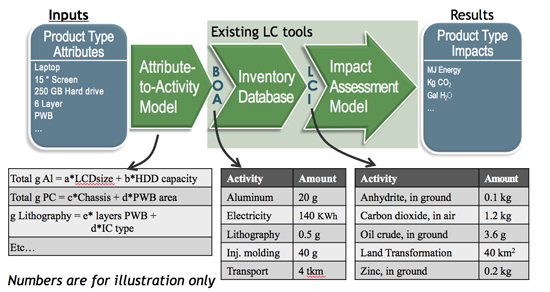

Simply put, PAIA maps important attributes of a product, such as those with a high environmental impact or those important to stakeholders, to a product’s carbon and energy impact. Examples of attributes include laptop’s screen size, the size of the hard drive, or the area of a printed wiring board. These attributes are correlated to activities, such as manufacturing processes or transportation. Taking a hard drive as an example, this model considers all of the materials used in the manufacture of the product. Using existing LCI data, the model takes into account the amount of aluminum that a hard drive contains, the process to manufacture this aluminum, and then calculates the impact associated with these processes. Similar models are constructed for the materials and processes of the most import, which are then built into an algorithm encompassing the product family as a whole. The resulting product allows users to get a reasonable estimate of the carbon and environmental impact with a fully understanding of the uncertainty contained within the results.

PAIA Home | Research Approach | PAIA Tools | Harmonization | Learn More